The drawing in the book is only applicable to LED's with a single bond wire. High efficiency red LED's are also like that. so they need two wires coming from the surface. White and blue led's are built on an isolator. consult datasheet to find out how the A/K assignment is done. The Cree LED is not a PLCC-2 but a PLCC-4 package. This stuff also only applies to 2 pin LEDS. the substrate is conductive so they just silver-glue that on the pin and done. In a normal LED ( red green yellow ) the substrate is the cathode and the bond wire the anode. As for the LED marking deviating from the explanation in the book : White and blue LED's have two bond wires.

EDGE REFLOW TUTORIALS FULL

if there is too much tie between full evaporation and solder liquifying the solder will oxidize and the wetting will not be good. If the solder starts melting while there is still flux it will 'spatter' and little droplets of solder may get flung all over the board and form tiny little balls. A fraction of second later the solder starts melting. This is the point where all flux has evaporated and we are now left with pure solder powder. At 24:16 the 'shiny' portion has gone away completely and the solder paste turns dull. The surface is nice and shiny 'wet' because of the flux. a couple of things to watch for in the video Time index 24:00 : as Dave is applying circular motion : you first see the solder paste 'sag' it goes from a nice 'sharp' edge to a puddle. Solder paste properly stored airtight can be used well past its 'expiration' date. If that stuff settles you won't be able to squirt it out anymore. Leave that tub or syringe open and the flux will slowly evaporate and absorb moisture from the air basically destroying it. Fluxes can be hygroscopic ( especially the water soluble ones ) and part of the flux evaporates as well. 2) Capping the paste container air-tight. it becomes impossible to squirt it out of the syringe and if it comes out of the tub you have to re-stir it to homogenise it. So the emulsion is now no longer an emulsion and this gives problems. if you let the syringe or cannister sit at room temperature the solderpowder will slowly float to the top ( believe it or not but the granules of solder are so small and the flux so dense that that stuff actually floats on the flux. The reason for that is to avoid separation of flux and solderpowder. Two bits of background info of which the 'why' was not explained : 1) solder paste in the fridge. Or use those disposable spackling or plaster applicators. The functionality for viewing breakpoints is good as well as the colour coding though care needs to be taken to avoid accidently deleting - a popup would be good.That rubber spatula is waaaay to soft.

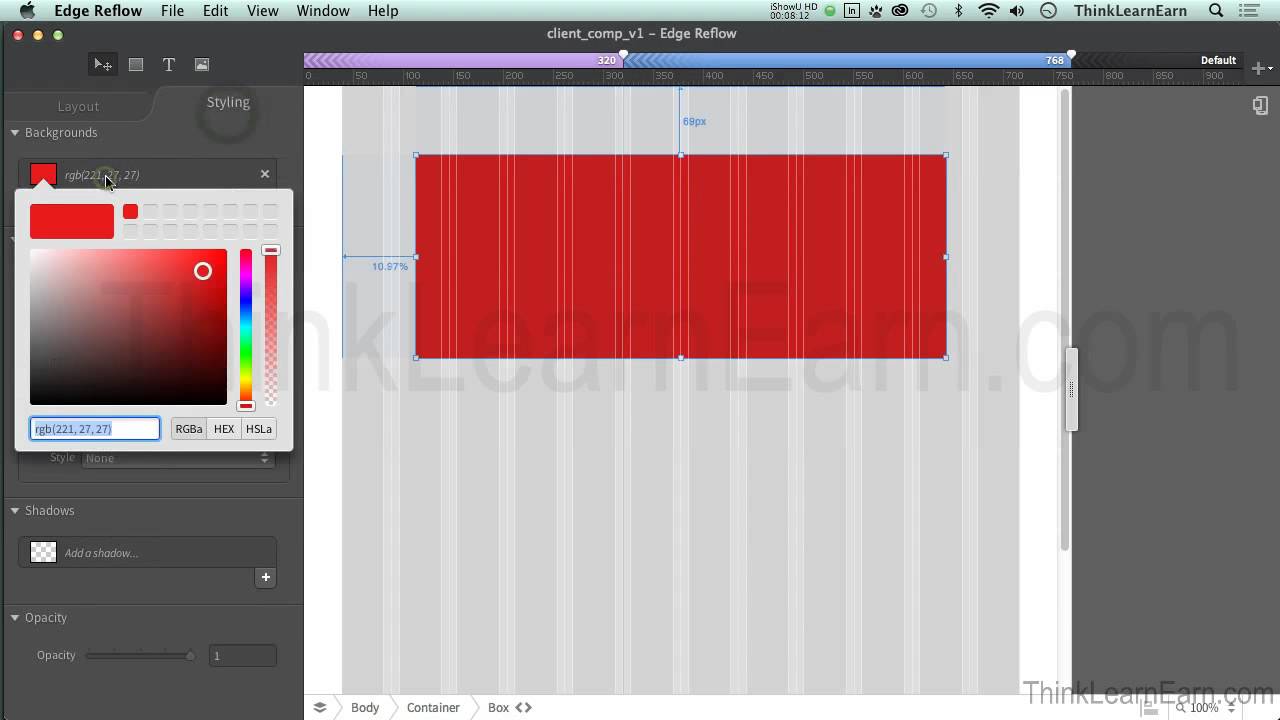

EDGE REFLOW TUTORIALS CODE

My primary use currently is mockups however was still interested in reviewing the code with the developers, though will have to hold off on this. Generally the tactile feedback for the application needs to be improved - basic things like hover / mouseover effects that are standard in adobe software.And if chaning to pixel dimensions, I have had it change to percentage. Alignment is a challenge, If I create a box and drag it to align, the magnetic/snap-to alignment function works however it is never 0%, it is always a fraction such as 0.4% and has to be corrected each time in the properties.It is frustrating when object are aligned and are not touched or interferred with by any other settings suddenly lose their global settings and develop individual settings with their own new dimentsions. If I set a margin to 10% for example and select a box or text field, why will it then display 9.86% on the object? (the percentage changes slightly when the page is expanded / closed).

Like-wise for a group of object should inherit identical properties.

0 kommentar(er)

0 kommentar(er)